Corporations, retailers, school districts, healthcare facilities, architects and facility managers are all looking at ways to lower costs to their operation. Many facilities have transitioned away from legacy flooring types and have chosen polished concrete. The perception is that although polished concrete restoration may be costly up front, the long-term maintenance costs will be reduced in comparison to other flooring options. This may be true, but often the performance benefits are oversold and facility managers fail to recognize the unique challenges with maintaining these surfaces.

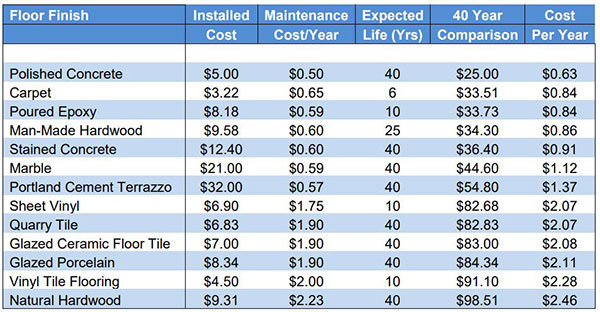

Life Cycle Cost for Floor Finishes

*Michael Doyle Partners, Flooring Comparison Report 2017 pp 12

Fact: All flooring options require some element of maintenance.

Fact: All flooring options require some element of maintenance.

- Abrasion – the finish on a grand piano may be flawless for years, but you don’t walk on pianos. Gloss reduction occurs over time as floors experience wear. This abrasion occurs from dirt and foot traffic, creating microscopic scratches.

- Dirt Embedment – Our shoes track dirt into facilities from the outside world. Porous materials are receptors for this dirt which becomes ground into the floor over time.

- Staining – Accidents happen. Custodians desire an easy, low-cost method to repair these stains.

What Are Some Polished Concrete Maintenance Challenges?

What Are Some Polished Concrete Maintenance Challenges?

- Porosity – As concrete cures the evaporating water creates pores. Some of these openings are sealed by polishing but it’s nearly impossible to create a non-permeable surface. Have you noticed how wet concrete becomes darker? This is from water absorbing into the concrete pores. This porosity creates a challenge for dirt and stains.

- Stains – Also referred to as etching. You may be familiar with the splatter stain in your neighborhood grocery store pickle aisle. This is because concrete is etched when an acidic liquid is left to penetrate into the concrete pores.

- Reparability – Vinyl Composite Tile (VCT) is very easy to maintain. Depending on the blemish, the spot can be scrubbed or stripped and recoated and burnished back to an even appearance.

- Upkeep – Many concrete polishing systems finish with a coating called a “guard”. These guards are usually topical coatings that help resist staining and emit gloss. Often guards are used to reduce labor from truly polishing the concrete to a high gloss appearance. The challenge with guards is that they are sacrificial coatings that need to be maintained through recoating and burnishing. Guards also exhibit characteristics similar to coatings used for VCT. Therefore, facilities find themselves facing the same challenges that they faced with VCT, but now with a flooring type that they are less experienced at maintaining.

To learn more about polished concrete, click here. The Crete Rx™ System from Betco® uniquely addresses all of the challenges mentioned in this article.